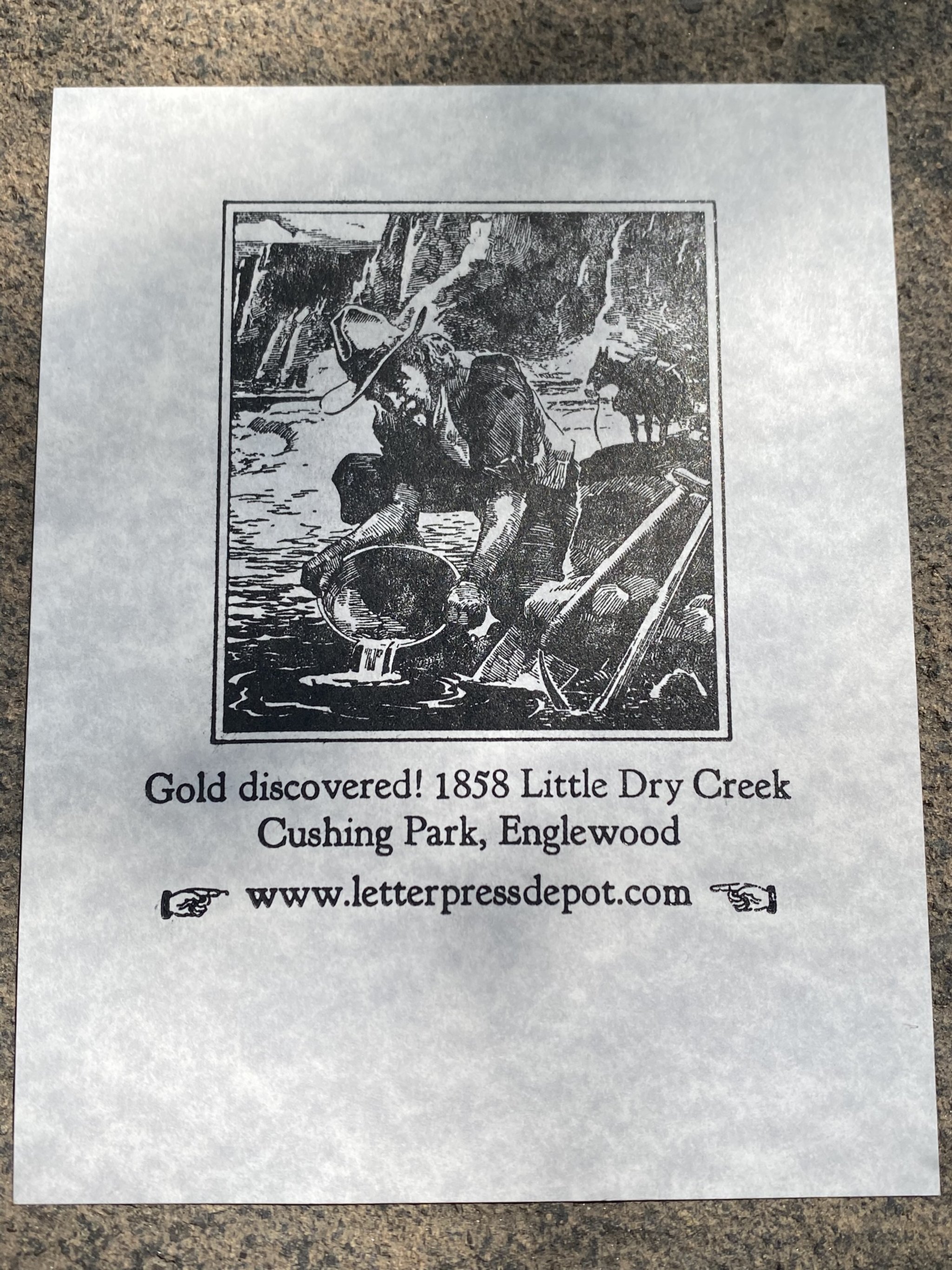

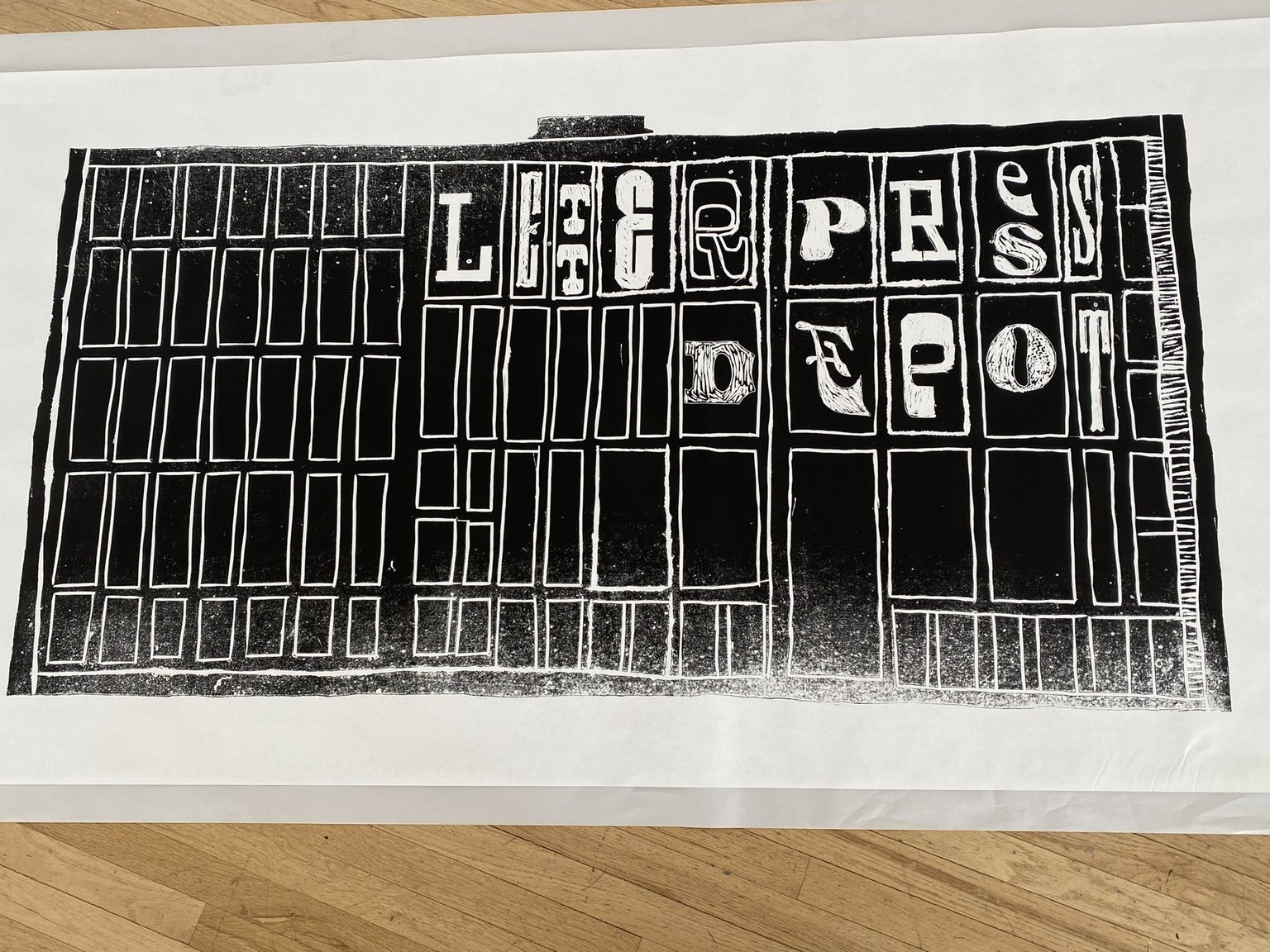

Colts Armory platen (on loan from Doug Sorenson) ~1887

The name given after 1887 to Merrit Gally’s Universal press, which he’d introduced in 1869. The former minister held more than 500 patents. John Thomson, who hated Gally from the first time he heard him preach as a child, ended up taking over manufacture of the press in a high noon standoff worthy of the Colt’s name. For more details of this history see https://bit.ly/3D4BXIy

Old Reliable platen press 8x12 1888

The Old Reliable was manufactured for just one year by H.H. Thorpe (Cleveland Type Foundry). James Thorpe held many other platen press patents, which he later sold to Chandler and Price. Used by hobby printer Jim Grisenti, it was donated to the Depot by Jim Fitzgerald in memory of printer Wimpy Miller.

Schniedewend & Lee Old Style platen Manufactured between 1884-93

This press also was built on the foundations laid by George Phineas Gordon. The Schniedewend company also built the Reliance A iron hand press on our east wall.

Damon-Peets platen, new style 9x12 (on loan from Doug Sorenson) ~1893

Calling itself the “latest improved Gordon,”whose “style supersedes all other presses” and which can print 2,000 sheets an hour, it was made by Damon & Peets of New York.

Next up: the Depot’s smaller presses…stay tuned! Come see them all March 26, Open Studio 10-4