What a way to end summer - by printing non stop at the Englewood Block Party…and at the Rocky Mountain Book & Paper Fair.

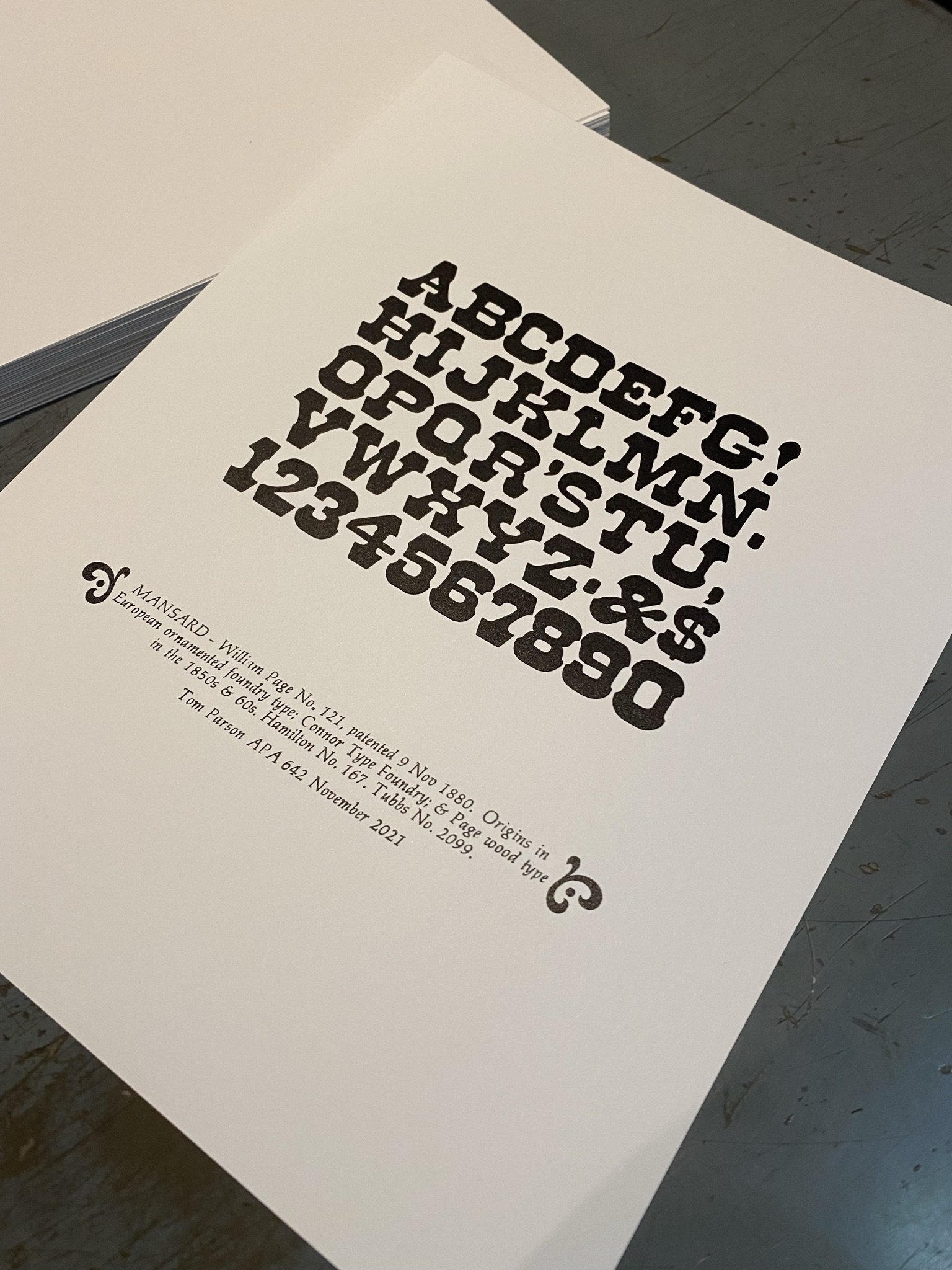

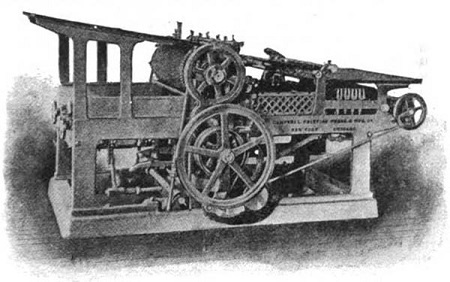

And by moving some old new presses and type into the Depot (check out that hanging press).

But we’ve only just begun! We just launched a capital campaign to help us get occupancy. With support from the State Historical Fund and individuals, we have raised over $200,000 towards our $550,000 goal. It sounds like a lot, but we are the little engine that could. We know we can! With everyone’s help, we can finish construction and open the doors. Your donation is an investment in the preservation of this historic building, the future of letterpress printing, book arts, and our continued community involvement. Donate at https://www.letterpressdepot.com/donate . All ABOARD!

If you know anyone who might want to donate, or if you have any questions, email us at info@letterpressdepot.com or call/text 720-480-5358. Follow us @letterpressdepot on Instagram and Facebook and @letpressdepot on X. Thank you!