“We don’t live out here no more,” he said. “Grandpa was the printer, over in Elkader, and after he retired he kept a little shop in the cellar.”

We went around back, and he opened the cellar doors – old-style double doors that revealed concrete steps going down under the house. It was a dank, cobwebby place. Engine parts and tools were piled against the wall. Boxes and old furniture were stacked everywhere. Tom pulled a chain and a bare bulb illuminated the space.

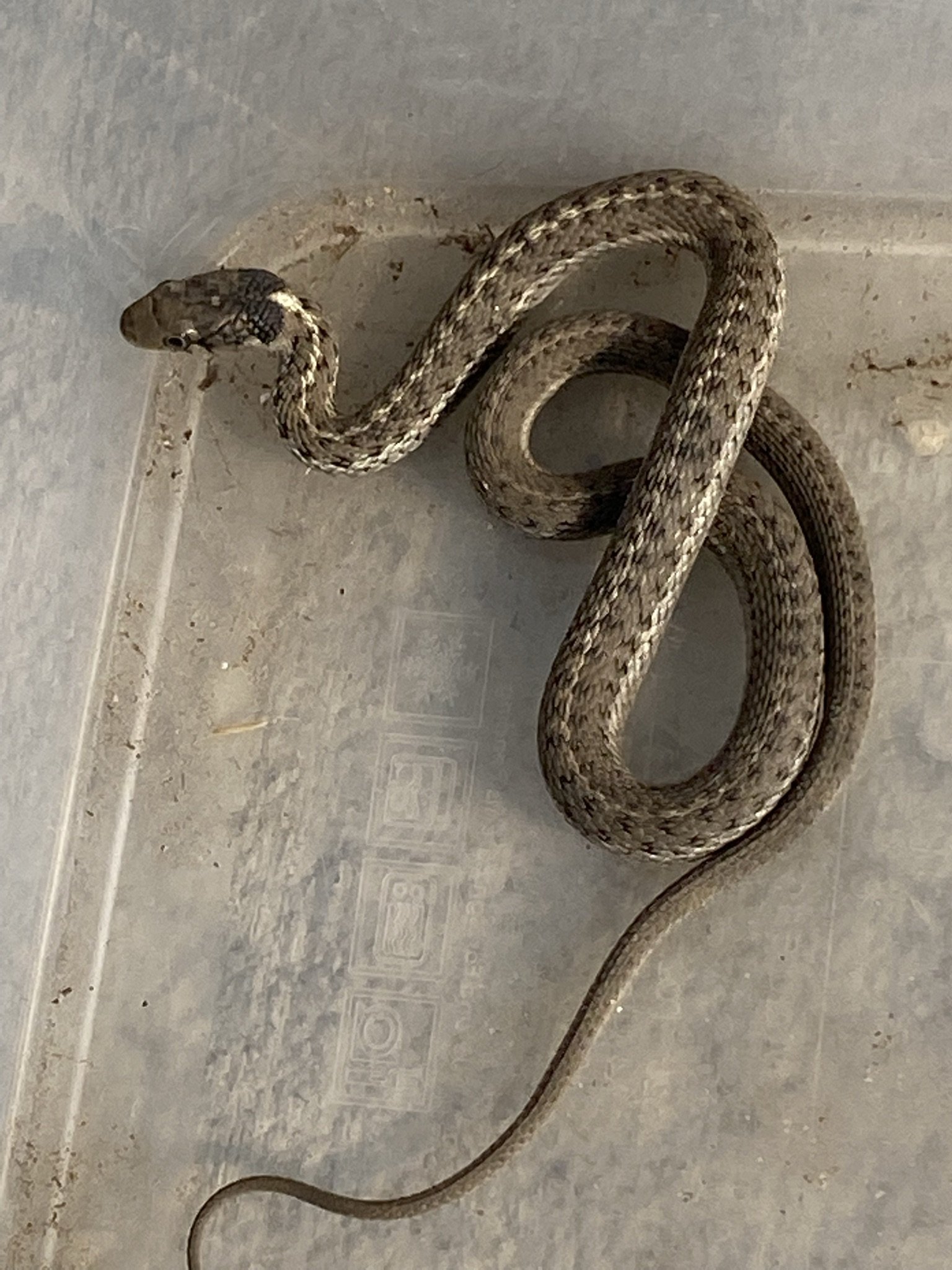

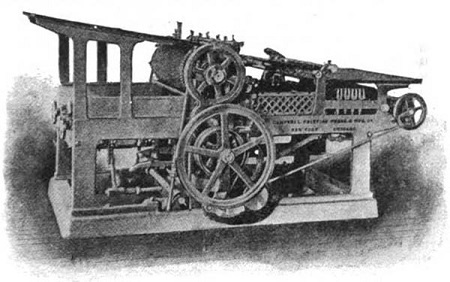

“It’s over here,” he said, and shoved a dresser out of the way. Back in the corner, the iron beast with its big flywheel sat forlornly.

“Is this where he did his printing?” I asked.

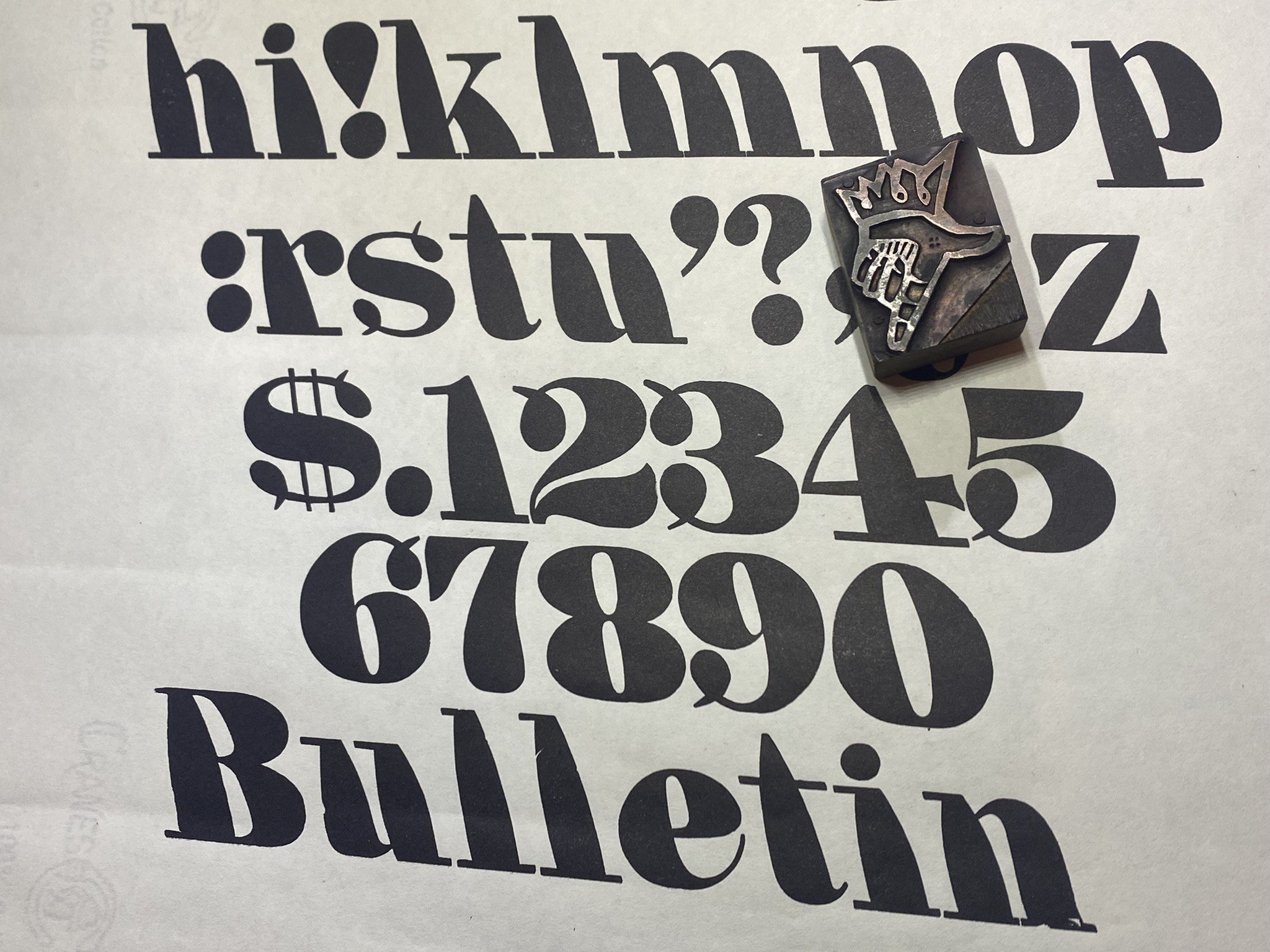

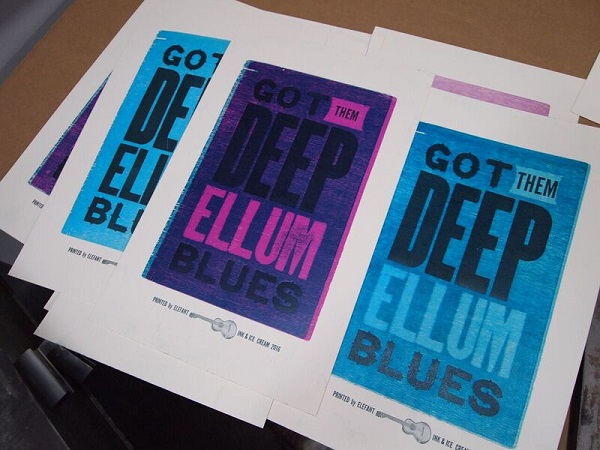

“Yup. I can remember Grandpa workin’ down here, and all those little metal pieces of type. He did the church announcements and other things - birthdays and flyers fer raffles and what not.”

“Any other old printing stuff around?”

“Let’s see … this cabinet is part of it.” He pulled a tarp off a wooden cabinet and opened some drawers. Ding bats and type, wood furniture. Despite the tarp, a leaky window had dripped for decades and damaged one of the sides of the cabinet. But is was old hard wood, and still sturdy.

Lingering over the family treasures, the old guy seemed to dwell on old memories. Then he blurted, “Well, we got some type, some ruler things and gizmos here … whatever was for the printer is yours.”

Tom and I hauled the cabinet out of the basement ourselves – nine steps up, and tipped it into my pickup. I slid it toward the cab and roped it down.

Now I faced the main dilemma – moving the beast. I estimated it weighed about 1200 pounds. One strategy is to take it apart, which is not advisable due the likelihood of stuck gears and stubborn bolts. All advice was to definitely not fiddle with it, haul it straight out, if possible, and onto your truck.

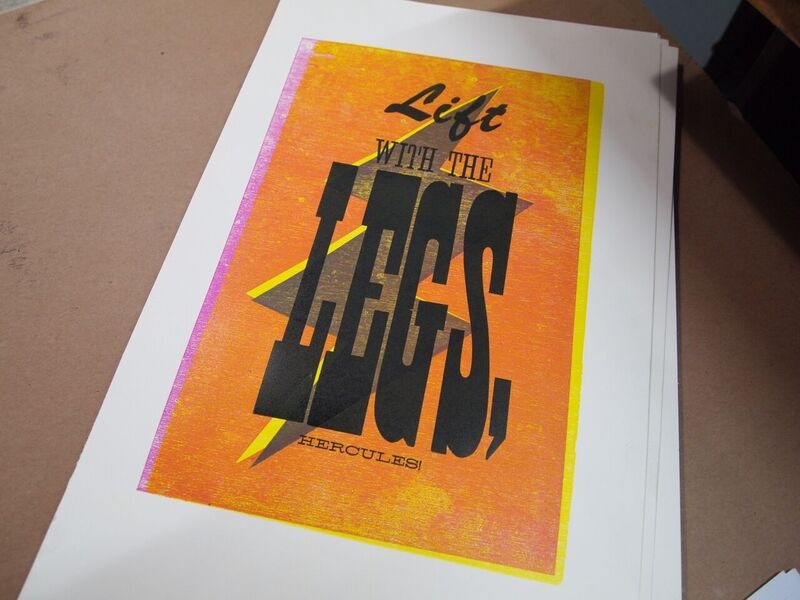

I got my winch, chains, boards and rollers from my truck and started clearing a path to the stairs. Metal pipes would serve as rollers. Luckily it was already bolted to hard wood 2 x 4s. A heavy duty pry bar could be wedged under one of the leg supports, to lift the beast just high enough the get one of the rollers in on the corner. Then the other corner. Then the backside too. Once on rollers, you could push it pretty easy.

At the stairs, I chained it around and tied my winch around a tree outside. Then, downstairs, I pried the beast up to the first stair, yelling to Tom to crank the winch. We did this till it was angled up onto the stairs’ incline, tipping a bit precariously but in position. I climbed over and out the cellar, and slowly cranked the winch, one inch at a time. I climbed back into the cellar, and out again, back and forth, making sure it was clearing the steps. One false move, or broken chain, and its cast iron limbs would be shattered. As rain clouds blossomed and distant thunder threatened ominously, the iron beast rose slowly, slowly emerging from its cave of some sixty years.

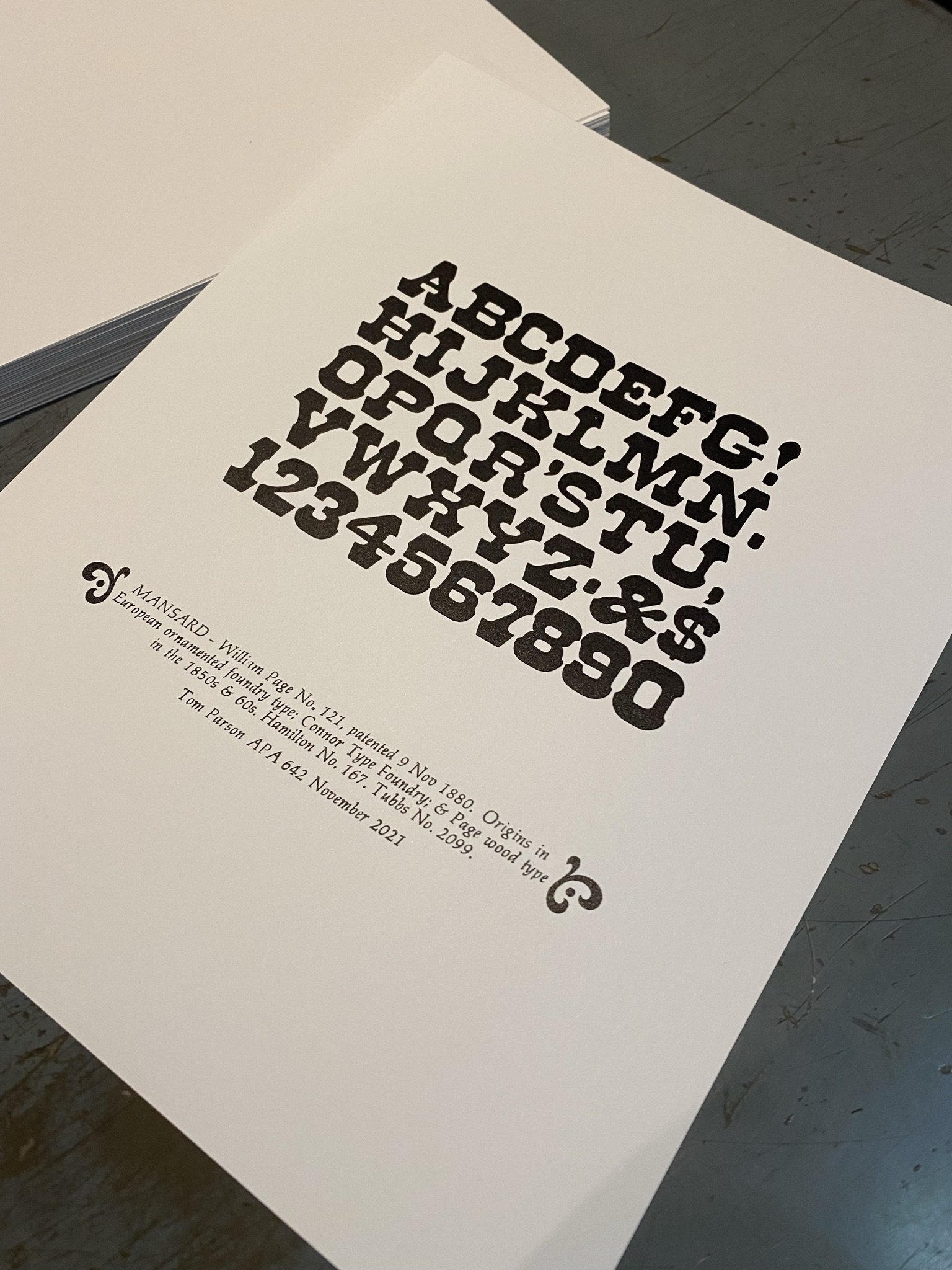

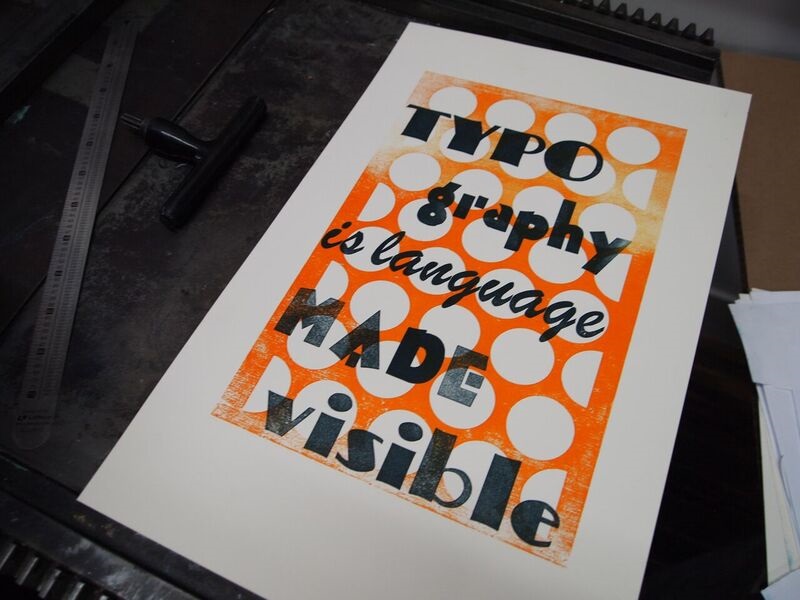

An Old Style Gordon, 8 x 12 chase size, never motorized, with intact foot treadle. Nice. Complete, no breaks or welds. With the V-shape throw-off arm, so an early model. Probably about 1890. Letterpress printing, a dying art, replaced by offset in 50s, and computer laser printing in the 90s. But it was real printing, with metal type, impressing the page with the inked type, just like Gutenberg did over half a millennia ago in the 1450s.

Outside, the second challenge became apparent: Hoisting it up my wooden ramp into my pickup. “Wait a minute,” Tom said, and disappeared into the barn. A few minutes later a trench digger tractor emerged, with a big dump bucket on the front. “I see what you have in mind,” I said. “Let’s chain it up!”

Together, we strategically wrapped chains around the press and used the tractor’s bucket arms to lift the beast straight off the ground. I quickly back my pickup truck under it. Tom smiled at his ingenuity as he lowered it onto the bed. The rest was a mess of compression straps and ropes, a chore that always took me forever and made me feel like one of the Three Stooges, unraveling and retying endless knots. As the rain started plunking down, I bungeed a tarp all the way around. Wouldn’t want the beast to rust before we got home.

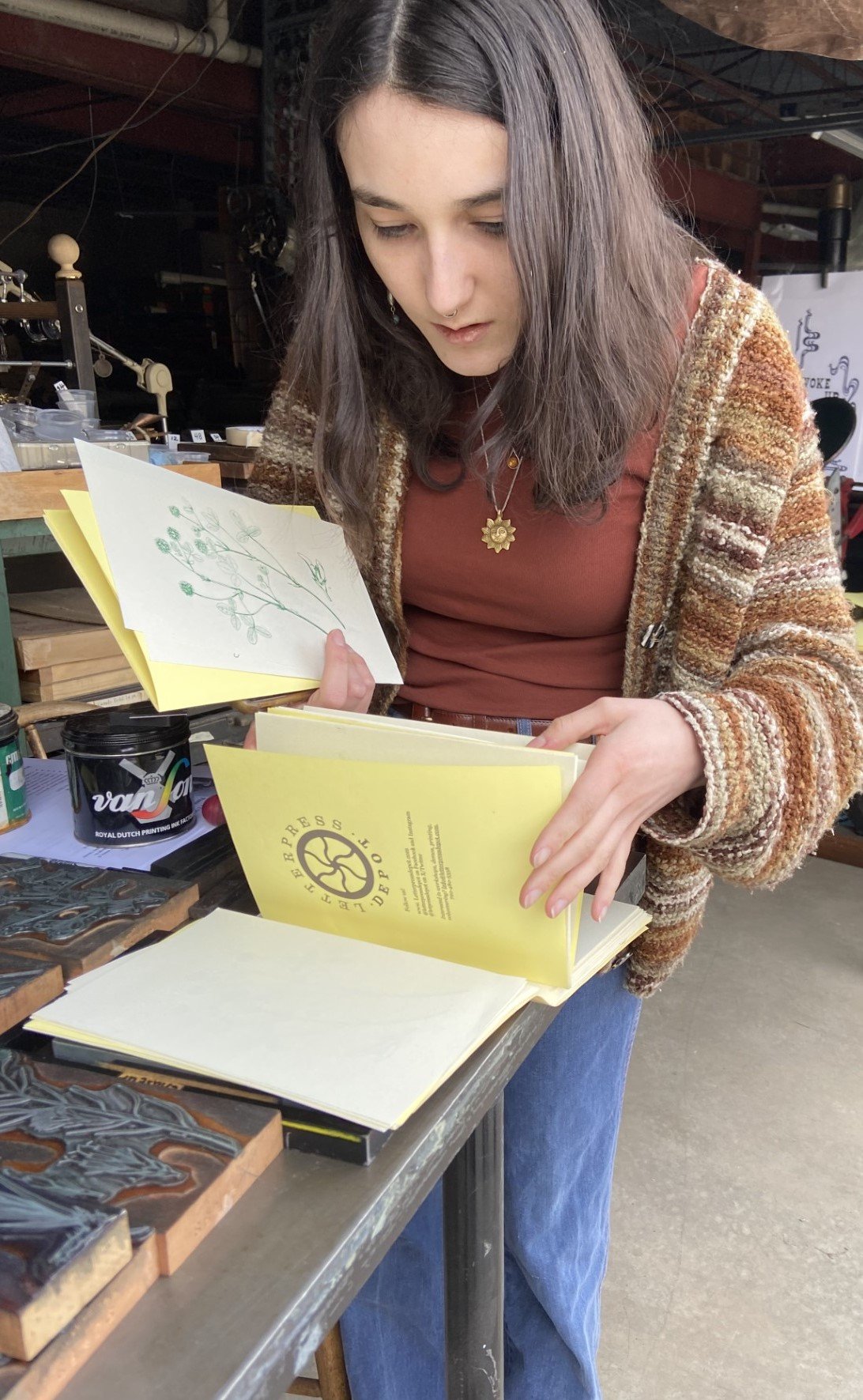

A couple hours of work, a few scraped knuckles, and it was mine. And $100. Tom had disappeared into the house. When he finally returned he handed me a book. A big old ATF type specimen book.

“Thanks, Tom,” I said.

“I was gonna scrap it,” he said. “But I just couldn’t bring myself to do it. Grandpa spent a lot of time with that machine. So I’m glad I found someone to use it.”

I waved as I pulled slowly away, with a 15-hour drive in front of me. Yeah, these old machines were discarded and scrapped wholesale in the 70s. But you still find a few around. Thank God for guys like Tom (and Craigslist), who make an effort to get them placed in caring hands. At 1200 pounds, he could have gotten $200 at the scrapper for it. ‘Course, you’d still have to haul that big old beautiful beast out of its cave. This is one beast that will live again, doing what it was born to do – press inked metal into paper and make books. Books that in all likelihood will far outlast digital printing.

(c) John Major Jenkins. Read more about his work: http://alignment2012.com/OakRootPress.html